KNOW THEPRODUCT

The MAINPOL bean bag factory is specifically designed for the production of EPS balls for bean bag filling using a machine designed for this. This installation is very easy to use and requires a very small space, as well as very few personnel and a low energy cost.

JOIN SUSTAINABLE MANUFACTURING

The EPS manufacturing process does not emit polluting gases into the atmosphere

FABRICATION PROCESS

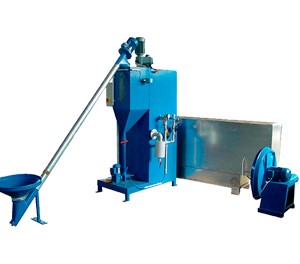

PRE-EXPANDER

The Pre-expander transforms the expandable EPS (raw material) into expanded EPS, achieving the necessary density depending on the production needs. It is an easy-to-use machine and a fully automated process.

BOILER

The steam boiler produces the water vapor necessary for the different phases of the expansion process (expansion of the raw material beads, welding and pressing of the block) It is fully automatic and requires minimal maintenance.

SILOS

The silos are used for the storage and rest of the expanded beads, while their stabilization occurs. The dimensions of the silos are very varied and adaptable to customer needs.

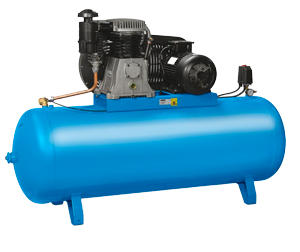

COMPRESSOR

The compressor produces the air necessary for the movement of valves, flaps, etc. The tank is a storage of the air produced by the compressor.

PUFF FILLING MACHINE

The filling machine is designed to fill puffs or bags with balls (eps) in a matter of seconds in a clean and precise way, pouring the right amount in each unit.

TECHNICAL DATA

- Necessary covered area: 100 m2.

- Production: 30 m3/h

- Necessary personnel: 1 operario.

- Production densities: 15-25 g / l first expansion and 9-15 g / l second expansion.

- Steam consumption: 200 kg/h.

- Fuel consumption: 14 l/h.

- Electricity consumption: 7 KWh.

*Approximate data, may vary depending on density, etc.